Tent Pole

FAQ's

WHAT YOU NEED TO KNOW FIRST:

The main things you need to determine are the diameter of the poles, the

length of the poles and whether the poles are aluminum, fiberglass, carbon

fiber or steel.

Do you have poles and don’t know what size they are? Click on the picture

below to download a chart of actual size pole dimensions.

ALUMINUM & CARBON FIBER POLES 101:

Easton Aluminum 7075-79 tent tubing. They are available in 9 different

diameters (.312, .340", .344", .355", .380, .433", .490, .625" and .742"-

outside diameter). Black anodized, 18" lengths and selective 13" and 26"

lengths. Custom make your own tent poles. Poles can be shortened if

necessary to custom lengths, and shockcorded together.

Easton's Custom Carbon 6.3 poles are extremely light, high performance

carbon graphite tent pole system. Carbon 6.3's have similar performance in

stiffness, strength and deflection to Easton's .340" poles but with a 25-30%

weight savings. These poles can use all of the components (endtips, inserts

and angles) as the .340" aluminum poles.

Note that Carbon tubing reacts differently than aluminum to situations

involving abuse and extreme use, such as crushing, prolonged abrasion or

incomplete ferrule insertion (which could cause splitting at the tubes'

ends), the weight savings attributable to carbon are accompanied with a need

for more vigilant care and proper treatment. With proper care, Easton carbon

tubes will last as long as Easton's aluminum tubes.

If you need to shorten carbon fiber poles wrap the pole with tape over

the area that needs to be cut to keep it from fraying. Using a

hacksaw or a pipe cutter (we sell it separately) trim the pole to the proper length.

THINGS TO KNOW BEFORE YOU MAKE

A POLE:

There are 2 types of poles:

(1) Poles with inserts -the insert is a tube (or sleeve) that is typically

glued inside one hollow end of a tent pole section and protrudes

approximately 1 1/2". This insert allows you to stack one section on top of

another.

(2) Poles without inserts-these are hollow poles (sections) with no

inserts

To make a set of poles it is usually best to map out on paper to determine

how many sections and parts you many need of each. You will usually need

more sections with an insert than those without. For example if you want

to make a pole with 4 sections (this would make a 6 foot long pole), you

would need to have 3 sections with an insert and 1 without an insert. The

reason you need the last section to be without an insert: picture stacking

one section with an insert on top of another. If the last section has an

insert, that would not allow you to put an endtip into both ends of the

pole. Therefore if you use a section without an insert for the last one you

will have a hollow end on both ends of the pole, this allows you to put an

endtip on each end of your pole.

HOW TO MAKE ALUMINUM & CARBON FIBER POLES:

Step #1 Lay out your poles in the order you want them. (cut them to the

right length, if it is necessary, using a hacksaw or even better a pipe

cutter (we stock these for your convenience). Note: If you need to shorten

carbon fiber poles wrap the pole with tape over the area that needs to be

cut to keep it from fraying.

Step #2 Knot one of the endtips onto to one free end of the shock cord and

push it into one of the hollow ends of the pole sections. Thread your shock

cord through each pole section.

Step #3 On the other end, tie the other endtip onto the shock cord. Push

the second endtip up into the other hollow end of the pole. Test the

tension; you do not want it too tight that when they are folded up they want

to spring open. If the tension needs to be re-adjusted, re-tie the knot.

If the shock cord is not tight enough remove the end tip and re-tie it a

little tighter.

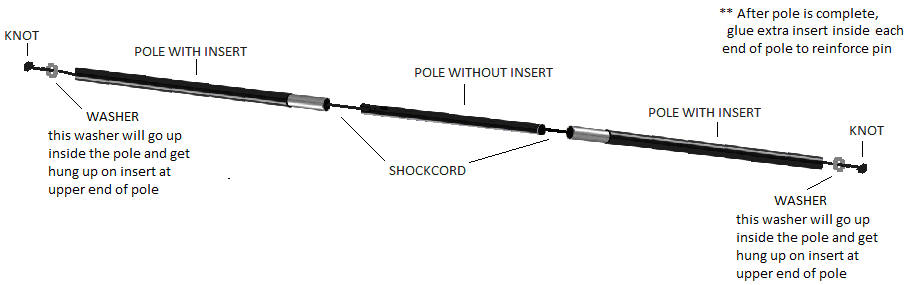

Pictured above are both types of tent pole sections: the two sections on the

right are sections with an insert. The last section on the left is a

section without an insert. Using the pole without an insert at the end

gives you a hollow end on both the rightside and leftside of the long pole

to insert the tied-off endtips.

You're Done!!

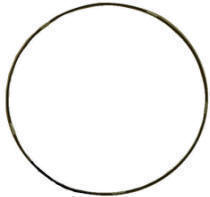

How to shockcord poles together without using endtips-(ie. ring and pin

system):

For your ring and pin system the best way to shockcord the poles together is

to tie the shockcord onto a small washer that is just slightly smaller than

the inside diameter of the tent pole. When the washer is pushed up into the

pole the insert on the first pole will stop it from going past. You can

then feed the shockcord through the rest of the poles making sure to put one

pole without an insert in the center or your chain of poles. On the opposite

end of the pole sections you again tie another washer onto the shockcord

and let it go up inside the pole (note you will not be able to adjust the

cord tension after this is done as the knot and washer will be way up inside

the pole). This method allows you to shockcord all of the poles together

and have a hollow end on each end the pole sections to fit into your ring

and pin at the bottom. We have separate insert pieces that will fit up into

the poles. This will allow you to glue these extra inserts onto the hollow

ends of the poles to give you more structural support in the pin.

DIAGRAM FOR RING AND PIN ASSEMBLY

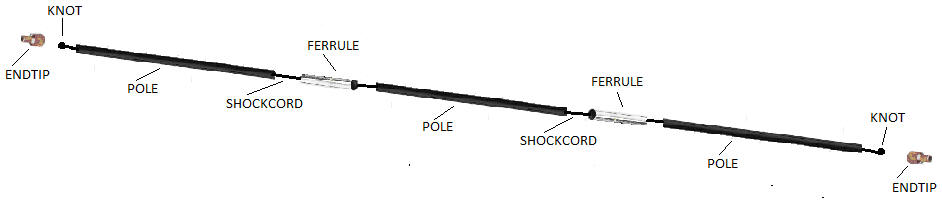

HOW TO MAKE FIBERGLASS POLES:

Making or repairing your own poles is easy just follow the step by step

instructions below...

Step #1 Lay out your poles in the order you want them, remember to put a

ferules (connector) between poles when needed, cut them to the right length,

if it is necessary, using a hacksaw or even better a pipe cutter (we stock

these for your convenience). ). Note: If you need to shorten the poles

wrap the pole with tape over the area that needs to be cut to keep it from

fraying.

Step #2 Glue ferrules on

Step #3 Put a knot in one end of the shockcord. Thread the unknotted end

of your shock cord through each pole section. When all of the poles are

threaded tie a knot in the other end. Test the tension; you do not want it

too tight that when they are folded up they want to spring open. If the

tension needs to be re-adjusted, re-tie the knot.

Step #4 On the other end tie the other endtip onto the shock cord. The

tension will vary but as a rule of thumb do not pull too much tension on the

cord-if you do when you break down the poles they will want to instantly

spring back into shape and they will be hard to pack away. Push the second

endtip up into the other hollow end of the pole. If the shock cord is not

tight enough remove the end tip and re-tie it a little tighter.

You're Done!!

shockcord How much & what size do you need:

To determine the amount of shock cord you need as a general rule you use as

much shockcord as the total length of the poles you are stringing (ie: an 8

foot pole would use 8 feet of shockcord). Usually by the time you tie your

knot there is enough tension but if you need them tighter just re-tie it

tighter.

As a general rule to determine the amount of shock cord you need:

For 18" poles add the number of all the pole sections you want to shock cord

together and divide this by 2. ie: if you want to shock cord 8 sections together you would

need 4 yards of shock cord. For the 26" poles multiply the number

of poles by 26 to get the total of inches. Divide this number by

36 and this will give you the amount of yards. ie if you have 9 sections

together you multiply 9 x 26" = 234" divided by 36 = 6 1/2

yds

The standard size shockcord for most aluminum and carbon fiber poles is 1/8"

(our item #2400) but when weight is more critical you can use 3/32"

shockcord (our item #2402). The standard size for fiberglass is the

3/32”.

How to attach inserts in ALUMINUM poles:

If you purchase the pole inserts separately you can use epoxy glue (like Loctite

326, JB Weld, a super glue or any glue suitable for metal, we like Gorilla

Superglue with the brush applicator) to

insert them into a tube section.

HOW TO BEND POLES:

The best poles to bend into an arc are the .340" and the .433". If you have

at least 6 of these poles together they will arc very easily. The easiest

way is to put one end of the pole section in the tent grommet or pocket and

ease the other end of the pole section over to the opposite tent grommet or

pocket. The center pole will usually be the only pole that will have a

small permanent arc in it but the arc is usually so minimal that it will not

stick out when all of the poles are broken down to pack away. NOTE: it is

usually best to try to arrange your poles so that at the peak of the arc

you have the center of a full pole (not an area where two pulls meet

together. It is weaker where the sections meet with each other and could

break).

If you are only using a few poles and you need to make a very strong

arc several customers have told us that if you pack it with play sand before

you bend it this will keep it from kinking. You also may want to

consider using pre-bent arches (see more info below).

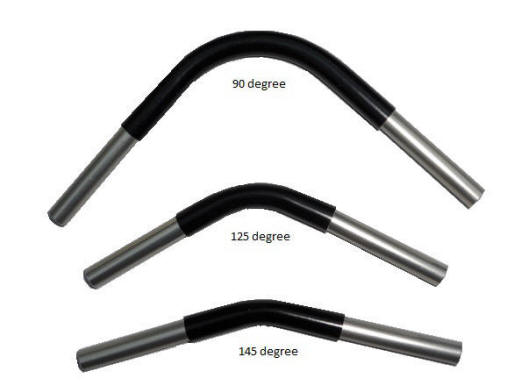

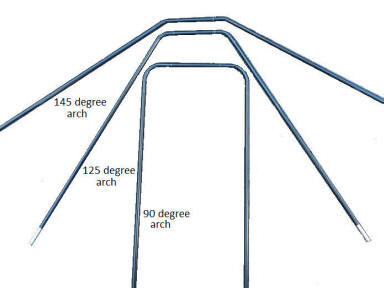

PRE-BENT ARCHES:

Pre-bent arches are available for the .340", .433" and .490" poles.

They are available in 90 degree, 125 degree and 145 degree. All of the

arches come with inserts already attached in each end, there are more

detailed measurements on the order page for each available size. Note,

when using arches you may want to draw out your configuration first as you

will most likely need more poles without an insert than with an

insert. If you are only using a few poles and you need to make a very strong

arc, to avoid kinking, you may want to consider using pre-bent arches.

Below is an example of using a short connector piece between two arches to

create tight angles without bending poles

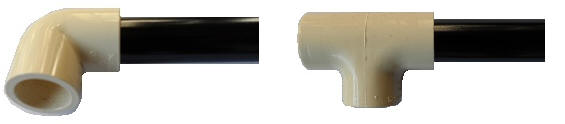

ARCHES FOR LARGER DIAMETER POLES

Aluminum arches are not available in the larger diameter poles but we

discovered that 1/2" size PVC parts, actually referred to as CPVC (45 and 90 degree arches, T's and

connectors) fit with the .625" diameter poles. These parts can be

found at local big box hardware stores (note they are typically found

separate from the standard PVC parts). NOTE: these connectors only

work the the .625" poles

TENT POLE COMPARISON

CHART FOR BENDING POLES

Do you need to bend a pole? The chart below lists each diameter

for the aluminum, carbon fiber and fiberglass poles and can be used as a

guideline to help you determine which pole diameter might be the best fit

for your project. The following is based on our experience of bending

the various size poles for use with light to mid weight fabrics.

Where the information is left blank above each pole diameter we feel

the span is too tight to make that kind of bend comfortably. Where the

information is blank below each pole diameter we feel that span is

too large for the pole to be supportive and sturdy enough. These are

based on our opinion and not a scientific formulation to give you a

guideline.

Note: any

reference to "poles" refers to 18" long poles for the aluminum (AL) ,

with the exception of the .742" which are 17", 17" long poles

for the carbon fiber (CF)and 25 5/8" long poles for the fiberglass (FG).

It does not matter what length of pole you use so long as the over all

length is the same (ie: 9 - 18" long poles = 162" which is equal to

6.2- 26" poles or 12.4 - 13" poles). Also, note that

especially with the aluminum poles, once they are bent the middle pole and

the ones on each side

of it may have a permanent slight bend).

| |

.340 and .344 (AL) |

0.355 (AL) |

0.380 (AL) |

0.433 (AL) |

|

least amt poles |

3 poles=40"

wide/20" ht) |

4.5 poles=52" wide/28" ht) |

5 poles=54" wide/31.5" ht) |

6 poles=72" wide/36" ht) |

|

1 ft span |

|

|

|

|

|

2 ft span |

|

|

|

|

|

3 ft span |

|

|

|

|

|

4 ft span |

35" ht (5 poles) |

42" ht (6 poles) |

|

|

|

5 ft span |

50" ht (7 poles) |

48" ht (7 poles) |

48" ht (7 poles) |

54" ht (8 poles) |

|

6 ft span |

44.5" ht (7 poles) |

49" ht (7.5 poles) |

45" ht (7.5 poles) |

55" ht (8.5 poles) |

|

7 ft span |

36" ht (6.5 poles) |

41.5" ht (8 poles) |

47" ht (8 poles) |

47" ht (8 poles) |

|

8 ft span |

24" ht (6 poles) |

36" ht (7 poles) |

42" ht (9 poles) |

42" ht (8 poles) |

|

9 ft span |

|

|

|

36" ht (8 poles) |

|

10 ft span |

|

|

|

|

|

11 ft span |

|

|

|

|

|

12 ft span |

|

|

|

|

|

13 ft span |

|

|

|

|

|

14 ft span |

|

|

|

|

|

15 ft span |

|

|

|

|

|

16 ft span |

|

|

|

|

| |

|

|

|

|

| |

|

|

|

|

| |

0.490 (AL) |

0.625 (AL) |

0.742 (AL) |

|

|

least amt poles |

7 poles=84" wide/41.5" ht) |

10 poles=108" wide/53" ht) |

|

|

|

1 ft span |

|

|

|

|

|

2 ft span |

|

|

|

|

|

3 ft span |

|

|

|

|

|

4 ft span |

|

|

|

|

|

5 ft span |

|

|

|

|

|

6 ft span |

54.5" ht (8 poles) |

|

|

|

|

7 ft span |

64" ht (9.5 poles) |

|

|

|

|

8 ft span |

66" ht (10 poles) |

|

|

|

|

9 ft span |

53.5" ht (9 poles) |

|

|

|

|

10 ft span |

53.5" ht (9.5 poles) |

59" ht (10 poles) |

|

|

|

11 ft span |

48" ht (9.5 poles) |

65" ht (11 poles) |

|

|

|

12 ft span |

48.5" ht (10 poles) |

60" ht (11 poles) |

|

|

|

13 ft span |

48" ht (9.5 poles) |

54" ht (11 poles) |

63" ht (13 poles) |

|

|

14 ft span |

47" ht (10 poles) |

|

65" ht(13.5 poles) |

|

|

15 ft span |

|

|

63" ht (14 poles) |

|

|

16 ft span |

|

|

|

|

| |

|

|

|

|

For the carbon fiber poles the first number

represents the least amount of pole sections we recommend

and the 2nd number is the most amount of pole sections we recommend

These are based on our opinion and not a scientific formulation to

give you a guideline. |

| |

| |

3.9 CF |

6.3 CF |

SYCLONE CF |

|

|

|

|

Note: pole sections are 17" |

|

|

|

1 ft span |

|

|

|

|

|

2 ft span |

|

|

|

|

|

3 ft span |

|

|

|

|

|

4 ft span |

5 pls (34" ht)-6 pls (43" ht) |

|

5 pls (34" ht)-7 pls (51" ht) |

|

|

5 ft span |

5 pls (30" ht)-7 pls (49" ht) |

|

4 pls (18" ht)-8 pls (58" ht) |

|

|

6 ft span |

5 pls (24" ht)-8 pls (54" ht) |

5 pls (22" ht)-7 pls (42" ht) |

5 pls (24" ht)-9 pls (63" ht) |

|

|

7 ft span |

5 pls (15" ht)-7 pls (43" ht) |

6 pls (27" ht)-8 pls (48" ht) |

6 pls (31" ht)-8 pls (52" ht) |

|

|

8 ft span |

7 pls (48" ht)-9 pls (57" ht) |

7 pls (32" ht)-9 pls (44" ht) |

6 pls (23" ht)-8 pls (48" ht) |

|

|

9 ft span |

|

9pls (48" ht) |

8 pls (48" ht)-9 pls (54" ht) |

|

|

10 ft span |

|

|

8 pls (43" ht)-9 pls (48" ht) |

|

|

11 ft span |

|

|

|

|

|

12 ft span |

|

|

|

|

|

13 ft span |

|

|

|

|

|

14 ft span |

|

|

|

|

|

15 ft span |

|

|

|

|

|

16 ft span |

|

|

|

|

| |

|

|

|

|

| |

|

|

|

|

| |

7MM (FG) |

9MM (FG) |

11MM (FG) |

|

|

least amt poles |

2 poles=39" wide/15" ht) |

4 poles=60" wide/36" ht) |

5 poles=72" wide/46.5" ht) |

|

|

1 ft span |

|

|

|

|

|

2 ft span |

|

|

|

|

|

3 ft span |

29.5" ht (3 poles) |

|

|

|

|

4 ft span |

33" ht (4 poles) |

|

|

|

|

5 ft span |

42" ht (4.5 poles) |

49" ht (5 poles) |

|

|

|

6 ft span |

40" ht (4.5 poles) |

51" ht (5.5 poles) |

58.5" ht (6 poles) |

|

|

7 ft span |

35" ht (4.5 poles) |

48" ht (5.5 poles) |

62" ht (6.5 poles) |

|

|

8 ft span |

|

47" ht (5.5 poles) |

59" ht (6.5 poles) |

|

|

9 ft span |

|

31" ht (5 poles) |

56" ht (6.5 poles) |

|

|

10 ft span |

|

|

59" ht (7 poles) |

|

|

11 ft span |

|

|

54" ht (7 poles) |

|

|

12 ft span |

|

|

|

|

|

13 ft span |

|

|

|

|

|

14 ft span |

|

|

|

|

|

15 ft span |

|

|

|

|

|

16 ft span |

|

|

|

|

HOW TIGHT WILL FIBERGLASS POLES FLEX

7mm POLES

4 1/2 POLES = 36" diameter (this is the

tightest these poles will go and that is pushing it )

5 POLES = 41" diameter

6 POLES = 50" diameter

7 POLES = 58" diameter

8 POLES = 65" diameter

9mm POLES

8 POLES = 65" diameter (this is the tightest these

poles will go)

(all diameters are approximate)

ENDTIP INFO

Endtips (those designed for grommets), regardless of the pole sizes: .340"

through .742" in aluminum, .342” for carbon fiber, or any size of fiberglass

poles, all fit into 9/32" grommets (also all fit into our 5/16"

grommets-which are known as a #1 grommet, our item #3231). Tie-off

endtips are used when poles are to be shockcorded together. Compression

fitting endtips are used when poles are not shockcorded together.

HOW TO DETERMINE HOW MANY

POLES YOU NEED:

If you have the original poles for the tent you can just measure those for

length. If you don't have the original poles you can try the following.

You can try an internet search for the specs for your particular tent.

Many times by "googleing" the tent manufacturer their site may list the specs

for your tent that will often include the pole specs. If you can't find

this information you may have to try to measure the tent from the point

where one end of the pole is inserted to the location where the other end is

located. We have found the following websites useful in determining the

length of poles.

Some Helpful calculator Links

http://www.worldwidemetric.com/metcal.htm (calculator for

metric conversions)

http://www.handymath.com/cgi-bin/rad2.cgi?submit=Entry

(calculator to measure length of an arc)

ALUMINUM TUBE SPECS

| ALUMINUM TUBE SPECS |

.340" |

.344" |

.355" |

.380" |

.433" |

.490" |

.625" |

.625"

(5086 STYLE) |

.742" |

.346" CARBON |

|

outside diameter of MAIN

tube |

.340"

(8.64 mm) |

.344"

(8.74 mm) |

.355"

(9.02 mm) |

.380"

(9.65 mm) |

.433"

(10.99mm) |

.490" (12.45mm) |

625"

(15.88 mm) |

625"

(15.88 mm) |

.742"

(18.85 mm) |

.346"

(8.79 mm) |

|

wall thickness of MAIN

tube |

.025"

(.64 mm) |

.019"

(.48 mm) |

.025"

( .64 mm) |

.026"

( .66 mm) |

.030"

( .76 mm) |

.026"

( .66 mm) |

.038"

(.97 mm) |

.038"

(.97 mm) |

.032"

(.81 mm) |

.028"

(.711 mm) |

|

inside diameter of MAIN

tube |

.290"

(7.36 mm) |

.306"

(7.77 mm) |

.305"

(7.74 mm) |

.328"

( 8.33 mm) |

.373"

( 9.47 mm) |

.438"

(11.12 mm) |

.549"

(13.94 mm) |

.549"

(13.94 mm) |

.678"

(17.22 mm) |

.290

(7.36 mm) |

|

|

outside diameter of INSERT tube |

.287"

(7.29mm) |

.303"

(7.70mm) |

.302"

(7.67 mm) |

.325"

(8.26 mm) |

.370" .

(9.4 mm) |

.433"

(11.0 mm) |

.544"

(13.82mm) |

.544"

(13.82mm) |

.675"

(17.15mm) |

.287"

(7.29 mm) |

|

wall thickness of INSERT tube |

.035" (.89mm) |

.021"

(.53 mm) |

.034"

(.86 mm) |

.034"

(.86 mm) |

.040"

(1.02 mm) |

.030"

(.76 mm) |

.045"

(1.11 mm) |

.045" (1.11 mm) |

.045"

(1.11 mm) |

.035"

(.89 mm) |

|

inside diameter of INSERT tube |

.217"

(5.51 mm) |

.261"

(6.62 mm) |

.234"

(5.94 mm) |

.257"

(6.52 mm) |

.290"

(7.36 mm) |

.373"

(9.47 mm) |

.454"

(11.53 mm) |

.454" (11.53 mm) |

.585"

(14.85 mm) |

.217"

(5.51 mm) |

FOR VOLUME ORDERS: IF YOU NEED 200 PIECES OR MORE OF ANY OF THE ALUMINUM

TENT POLE PRODUCTS AND CAN WAIT APPROXIMATELY 7 WEEKS FOR DELIVERY CONTACT US

FOR OTHER OPTIONS SUCH AS DIFFERENT POLE LENGTHS, COLORS, ETC. (NOTE: IF YOU NEED POLES WITH INSERTS AND POLES

WITHOUT INSERTS YOU WILL NEED TO GET 200 PIECES OF EACH).

QUEST TENT, NORTHPOLE and OZARK TRAIL CUSTOMERS:

We are NOT the makers of Quest Tents and have never been associated

with them or any other tent brand- it has been our experience these

past few years that Quest Tents seems to keep going in and out of business.

This is the last known information we have regarding them

http://questcanopy.net/about-us

If you are in need of an aluminum or fiberglass pole we may have a

replacement part or something that may work as a substitute but bear in mind

that we DO NOT have specs or know part numbers on specific Quest Tent models

or any other tent so we do not know the exact size or pole lengths needed

for each tent, you may need to look in your owners manual or google your

model to determine what parts you will need. I am sorry to say if you don't

see it listed on our website we do not have it Also, note that aluminum

pole parts do not work with fiberglass poles.

If you need a steel pole with a chain we do not carry them.

|